|

| Before: Mendel in Box |

The stepper motors I ordered were SM-42BYG011 from Sparkfun, but as I found out later, these weren't up to the job.

The whole build took 2.5 days, including cleaning all the RepRapped parts. I took 3-days of vacation and built the whole thing in one go. It was very therapeutic!

There were no major issues with the build, everything went smoothly. The biggest issue I had was with the X-carriage. The separation between the bearings was about 4-mm wider than the separation between the X-bars, so the bars were rubbing on the carriage and not riding on the bearings. This meant the carriage wouldn't move smoothly. A little work with a Dremel and a file sorted that out.

|

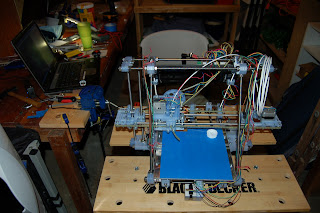

| After: Finished Mendel with first print (and build devastation in workshop) |

No comments:

Post a Comment